Energy Efficient + Security Window Films

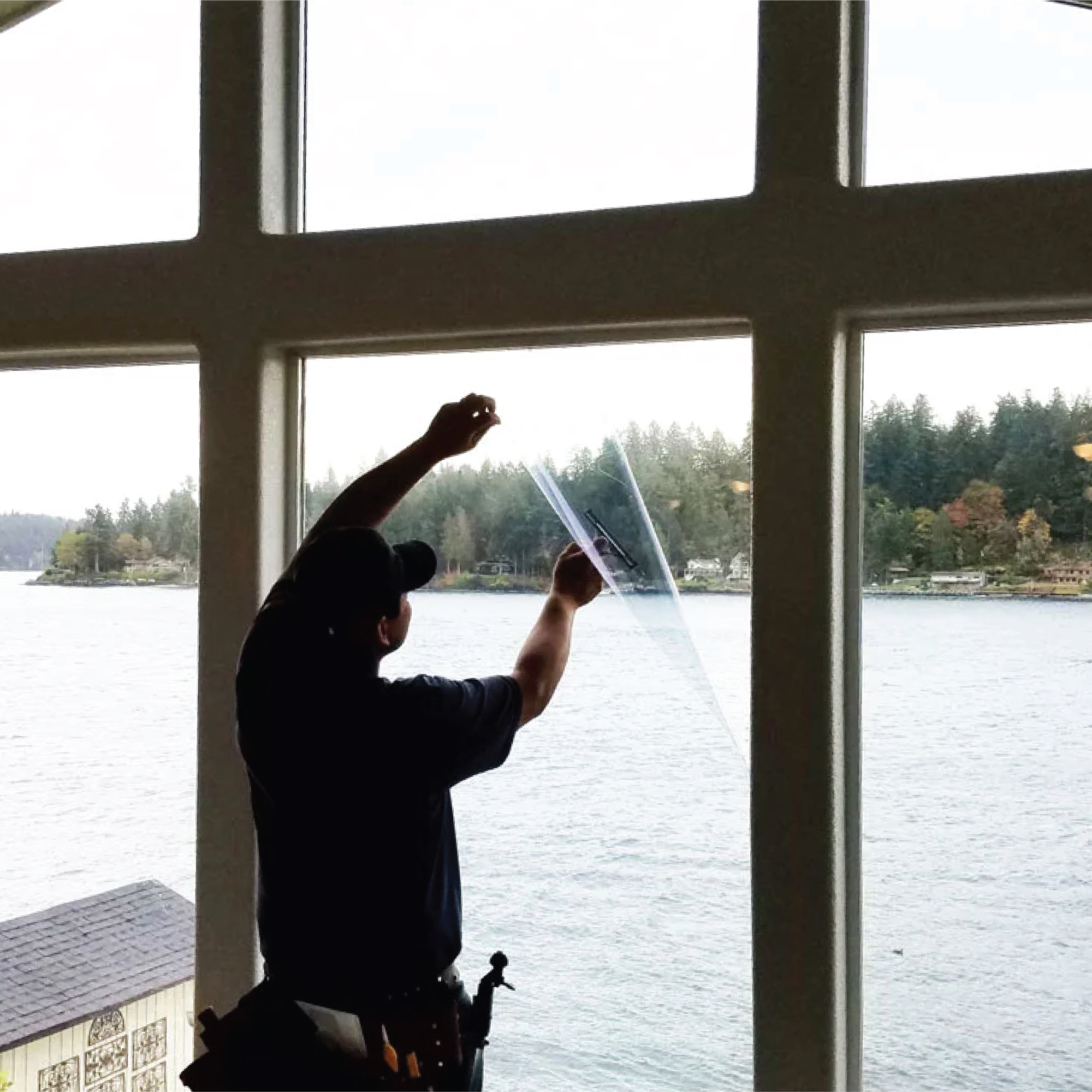

The cost-effective, modern day solution to heat regulation, insulation and security for homes + businesses.

Our films + coatings have helped thousands of people reclaim their living spaces, spaces that were once too hot, too cold, not private enough or not safe enough.

Shutting your blinds in the Summer to regulate the temperature inside your homes and businesses is now a thing of the past. Our films mean you can enjoy the outside while being inside.

A selection of our products allow heat to be retained, reflecting it back in to the room. A perfect solution for those looking to reduce living expenses and unlock the potential of your space.

Our films are also a great solution to privacy, safety, building regulations and glazing compliance. Mirrored, coloured, tinted and optically clear options available, suiting any space.

Frequently Asked Questions.

As experts & industry-leaders, our team understand your biggest concerns & most frequently asked questions, & they’re on-hand ready to answer them.

Not sure about legal regulations? Trying to solve a problem? Or simply need some design inspiration? Check out our carefully-compiled list of FAQs below, or browse our recent works to find out more.

How does one way / two-way film work?

“I want to see out, but want to prevent able to see in” is a common remark heard almost daily by anyone involved in the business of supplying or installing window film.

The reality is quite different than simply applying a layer of reflective window film to a pane of glass to achieve “one-way vision”. The secret lies not in the film or the glass but the prevailing lighting conditions.

Buildings with “mirrored” windows are now a common sight in most of our towns & cities. This is usually glass treated at the point of manufacture with a reflective coating or windows that have been retrospectively coated with a reflective solar control window film.

The reason why these windows appear mirrored from the outside yet can be viewed through from the inside is due to their metallised coating & the differential in external & internal light levels.

Why does a one-way window film not work at night?

The installation of reflective window film or glass within the external facade of a building does indeed afford privacy to the occupants but only during daylight hours.

During the hours of darkness with internal lighting in operation, the windows become “see-through” from the outside.

Because external facing windows often only require “one-way” vision during daylight hours such as offices, night time transparency is not usually an issue.

Why is the mirror film installed on my windows not working?

When the requirement for “one-way vision” concerns internal glazing such as office partitions or vision panels the effect is much more difficult to achieve & in many cases nigh on impossible.

Unlike external glazing, internal windows usually have similar amounts of light present on both sides of the glass. Should the light differential between the “private” side & the “viewing” side be less than a ratio of 1:7 this will probably result in total transparency or total obscurity from both sides no matter which way round the film is installed onto the glass.

To overcome this issue in an office environment where you have a window dividing two internal spaces, additional lighting can be introduced to one side of the glass or alternatively the amount of light on one side can be greatly reduced to produce the “one-way vision” effect.

Will window film cause my glass to break?

No, the application of Window film alone will not cause the glass to break!

However, we do understand that any application of Window film can cause an increase in temperature within the glazing system & will increase the stress on the glass edges.

The quality of the glass edges & several other factors (internal & external shading, glass history, type of film, type of glass, size & shape of the glass) all contribute to the potential risk of glass breakage.

How long will my Window Film last?

Ecofilms only uses the highest grades of film from reputable manufacturers.

Because of this & because we stand by the quality of our installations most of our window films are now warrantied for at least ten years with a total life expectancy in excess of fifteen years.

In recent years externally applied window films have become more readily available. Naturally, these films have to withstand more potential degradation due to climatic conditions however many of them are now available with seven to ten-year warranties.

All our externally applied films are edge sealed with a high-grade silicone sealant for added protection.

What causes the toughened glass to suddenly shatter for no apparent reason?

The main cause of the spontaneous breakage of glass is something called Nickel Sulphide Inclusion. Put in simple terms these are impurities present in toughened glass originating from the manufacturing process. Over time these “contaminants” are placed under stress causing the glass to shatter.

At ecofilms, we have safety films that can make safe and contain these rare occurrences, Get in touch if this is something you would like to learn more about.

What are the legal requirements for workplace maximum temperatures?

The maximum permitted temperatures in the workplace depend on what activity is taking place in a given place of work. For example, manual work will require lower temperatures than an office.

The Business Advisory Service advises ” Apply sun-control or other reflective films on south-facing windows to reduce solar heat gain”

It is generally accepted that thermal comfort for most people in the UK lies roughly between 13°C (56°F) & 30°C (86°F), with acceptable temperatures for physical work activities erring towards the lower range, & for less physical activities towards the higher end.

Will Window Film take away a lot of natural light?

It depends on which issues you need to address. If for example, you have a severe glare issue to resolve, it would be pointless installing a light or virtually clear film. After all, you wouldn’t buy a pair of sunglasses with clear glass in, would you?

With over a decade of dealing with solar-related issues, we at Lustalux are confident that we can match a product with your glass to provide a satisfactory outcome.

If you have overheating issues through your windows we can provide a solar control window film to deal with the problem with the minimum of impact on light levels. If however you also have a glare problem we will endeavour to strike the right balance between light loss & effectiveness.

In most cases, a small trade-off in light loss is more than compensated for in improved comfort levels.

What are the regulations regarding window manifestation?

Generally speaking, to comply with DDA regulations manifestation in the most basic form consists of two rows of markings in a material contrasting with the background of any full-height pane of glass.

One row should be at around 850mm & one row at around 1500mm from finished floor level.

They are a legal requirement under regulation 14 of the Workplace (Health, Safety and the Welfare) Regulations 1992, and the Building Regulations 2010: Document K.4 Protection against impact with glazing.

Think We Can Help?

Get in touch by sending a message to us below!